Working across the full asset lifecycle, we help clients to streamline workflows, mitigate risk, promote collaboration and reduce costs

Improve communication between all stakeholders, strengthen operator capability to respond and reduce risk across their assets.

Balancing fixed schedules and budgets, managing as-designed and as-built engineering data, compliance with HSE requirements and engaging a variety of stakeholders, both internal and third-party, who all require access to reliable and consistent data. These are just some of the challenges faced in the operation and future planning of an asset at Greenfield stage.

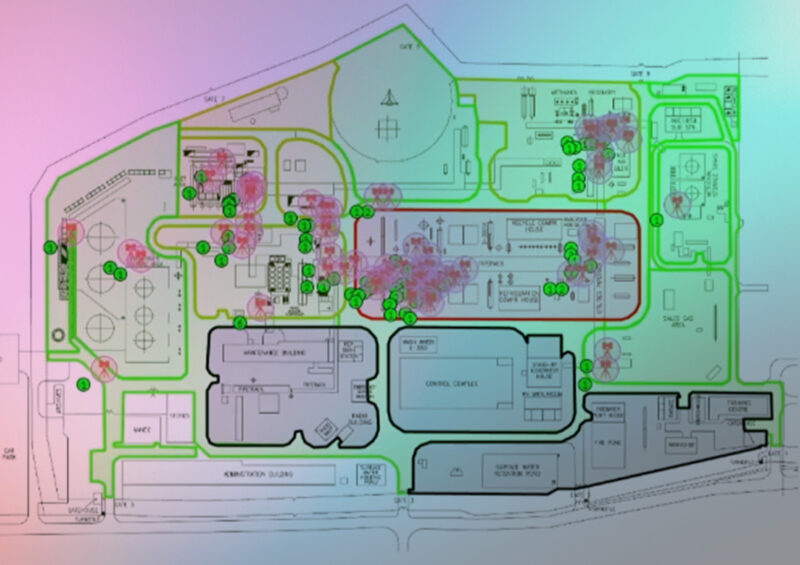

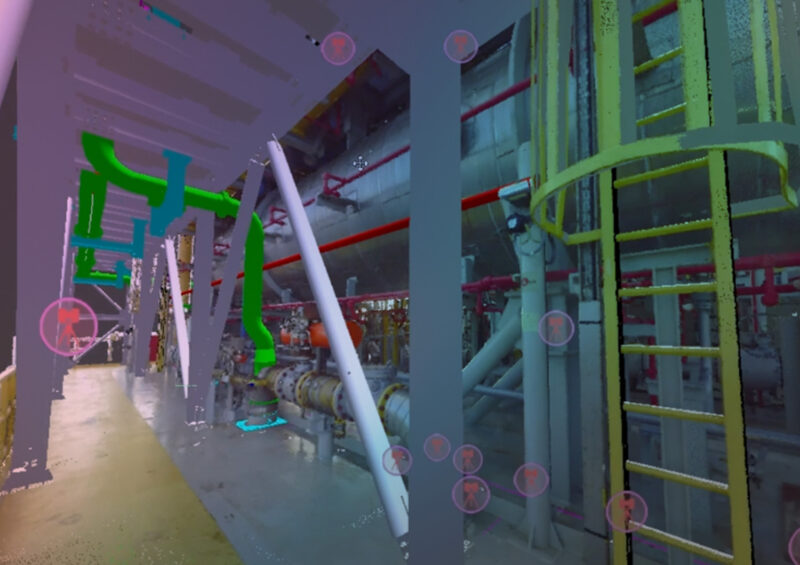

AS-TEG™ by eserv enables clients to centralise all necessary asset data streams into one easily-managed platform, to which access can be granted for remote asset familiarisation via 3D visualisation — making timely and precise design verification, HSE induction work and external contractor access simpler and more intuitive than ever.

Efficiency and integrity are vital to effective Brownfield asset management — and these are difficult to achieve when data streams are inconsistent, hampered by compatibility issues and challenging for relevant stakeholders to access. Costly on-site surveys are a natural recourse for this kind of uncertainty, but there’s a better, more efficient way.

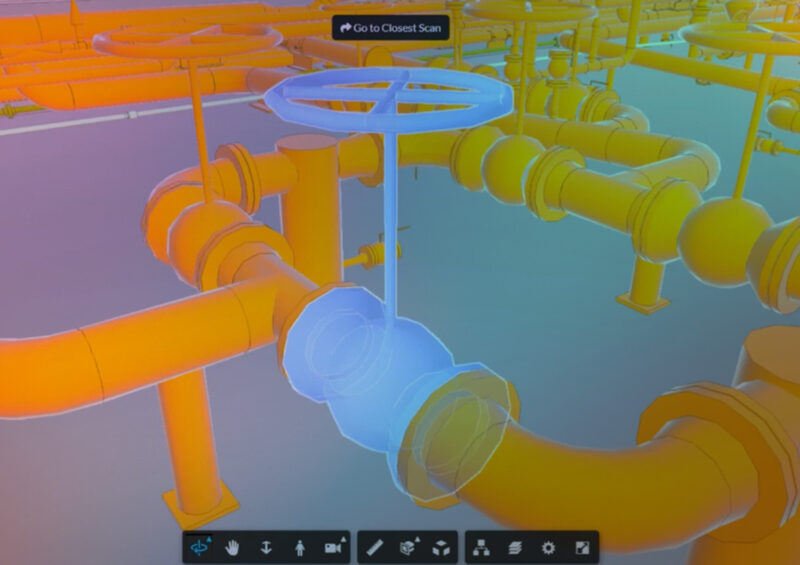

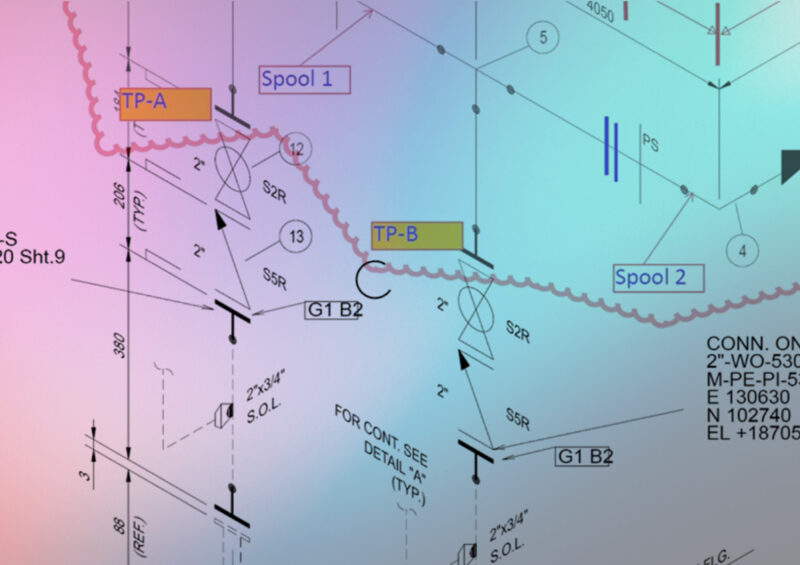

AS-TEG™ by eserv allows clients to access digital inspection isometrics and remotely-built 3D visual inspection models / reports, while integrating with existing inspection databases via API to ensure the whole history of your asset is accounted for in any engineering or integrity management work. The accuracy and access offered by AS-TEG™ allows for early identification of discrepancies / issues and, crucially, minimises the cost and schedule impact of on-site surveys and ‘failures to fit’.

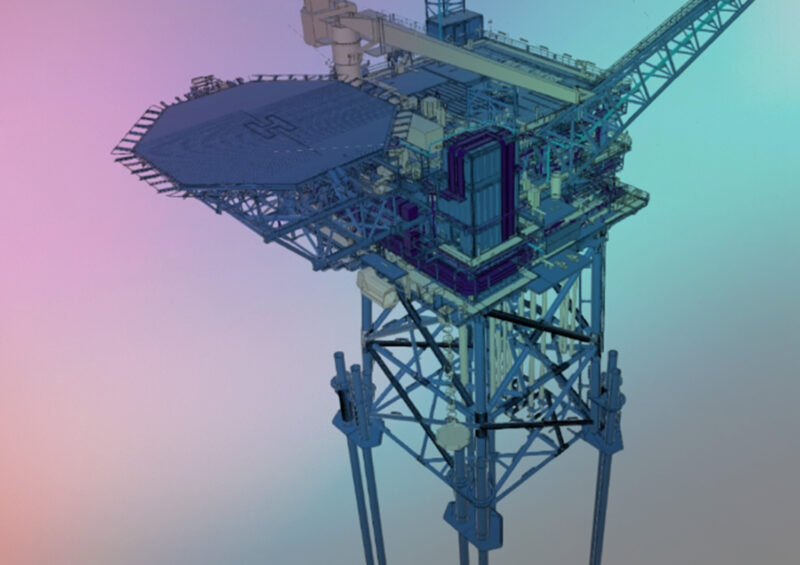

Managing the latter stages of an asset spans a variety of important processes — from surveys to inform strategic planning, decommissioning, recycling/repurposing processes and tendering for contractor bids on various end-of-life work scopes. Accurate, up-to-date and in-depth data is the path to efficient and cost-effective end-of-life projects, reducing risk and smooth contract handovers.

AS-TEG™ by eserv is an invaluable resource for Late-Life clients, offering remote survey capability that can remove approximately 60% of the usual on-site surveys required. We provide a neutral, integrated platform to allow all departments and external contractors to access the data they need. It also allows for remote stock taking of equipment and verification of equipment spec, eliminating the budgetary costs and schedule impacts of on-site verification wherever possible.

REAL-WORLD

AS-TEG™ APPLICATIONS

Explore how AS-TEG™ adds value to specific job functions with project teams across the asset lifecycle

WHERE AS-TEG™ SUPPORTS THE FULL ASSET LIFECYCLE

Constructibility reviews, fabrication isometrics, integrate with existing databases

Access to digital twin to third-party vendors, assign work orders for team

Seamless updates to ensure ‘as-built’ data

Digital P&ID verification, remotely generate inspection isometrics, discrepancy identification

Leverage precise ‘as-built’ point cloud model to avoid rescans

Rapidly respond to issues, minimise downtime, plan TAR / shutdowns

Fully ‘as-build’ and verify P&IDs

Price work scopes based on detailed asset data, reduce tender estimates from cost +40% to cost +5%

Optimise decommissioning using ‘as-built’ data for operators / regulators, track project progress

Case Study

Brownfield FPSO SAVINGS of over $4million in under 3 years since AS-TEG deployment

FAQs

Yes, AS-TEG™ provides a digital twin solution that offers an accurate, up-to-date, virtual representation of your physical assets. However, unlike some other solutions, we focus on delivering accurate, actionable engineering data through accessible, easy-to-use technology that supports better decision-making across all stages of the asset lifecycle.

Absolutely. AS-TEG™ is designed to integrate seamlessly with your existing data, regardless of its source. Whether it’s legacy data from previous surveys or other systems, we ensure it’s registered and usable within our platform, so you can maintain full control over your asset information without the need for complex conversions or proprietary formats.

Our team is made up of industry experts with hands-on experience across key sectors, including multi-disciplinary engineering, survey, maintenance. We’ve successfully deployed AS-TEG™ globally with leading operators, and our engineers bring this field experience directly into our solution to ensure it meets the highest industry standards.

Yes, AS-TEG™ is web-based, meaning it’s accessible from any device with an internet browser. Whether you’re using a desktop, laptop, tablet, or smartphone, you can access all of your asset data remotely, anytime, anywhere—no need for complex installations or software downloads.

Yes, AS-TEG™ allows you to share data with your chosen suppliers and project teams easily, at no extra cost. You can assign work orders, tag equipment, and share key engineering deliverables like inspection and fabrication isometrics. Our platform ensures data is stored securely and can be accessed and collaborated on with stakeholders both inside and outside your organisation.

AS-TEG™ is designed to support asset owners and operators across various industries, including energy (oil, gas, renewables), utilities, and infrastructure. Whether you’re working on greenfield projects, brownfield modifications, or late-life/decommissioning, AS-TEG™ is adaptable to any sector and asset type, providing actionable data throughout the asset lifecycle.

eserv expands into new Aberdeen premises to accommodate international growth

Brownfield FPSO SAVINGS of over $4million in under 3 years since AS-TEG deployment